New Veneer Dryers

New veneer dryers is meant for drying the Core Veneer & Face Veneer and is the Dryer of choice all over the country as well as abroad. Veneer Dryer is available in various sizes and different configurations from 5 Sections 1 Deck to 25 Sections 4 Decks. Biomass Veneer Dryer is the most economical dryer available because it consumes much lower power as compared to any other heating types wood veneer dryers. Our Jet Ventilated Roller Track Veneer Dryer can run on Steam as well as Thermic Fluid.

Type: Roller Veneer Dryer

Working Width: 4.5m

Veneer thickness: 0.8-8mm

Heating Area Length: 36m

Drying capacity (m³/day) : 180-190

Veneer Water Moisture: Fresh veneer to about 0-15%

Cost: 6-12$/m3 (Labor+Fuel+Electricity)

Heat Source: Biomass Burner (Other options available)

New Veneer Dryers

New veneer dryers is our newly developed product for high-end customers to meet the higher veneer drying capacity requirements of customers, which has the salient features of higher drying veneer capacity. The rollers use φ102 steel special shaft tube. The bearings of the 4 deck veneer dryer are featured high temperature 500 degree Celsius resistance and low temperature of -20 degree Celsius resistance which no need for injecting oil and easy maintenance in the daily operation. Equipped with biomass burner, which can ensure perfect drying effect and reduce drying cost mostly. The veneer after drying has a uniform moisture content, is flat, has no buckle or end waviness, good surface condition before gluing.

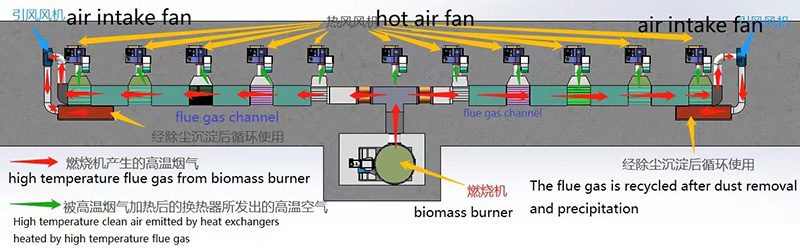

The Power of the Whole Machine is Reduced by 35%

The hot air fan and cold air fan of the dryer use the latest axial flow fans, which not only fully guarantees the air volume required for drying, but also reduces the total installed power and minimizes the power consumption of the entire equipment.

Heat Exchange System

Shine heat exchangers adopt step-by-step heat exchange. The specifications of the heat exchangers in each section are different. The hot air in the heat exchanger can be evenly distributed to the single board. The dried veneer has a uniform moisture content, is flat, has no wrinkles or end ripples, no cracks, and the surface is in good bonding condition, fully improving energy utilization and saving unnecessary energy waste.

Product Parameter of New Veneer Dryers

Model No | GTH45-40 |

Working Width | 4.5m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 36m |

Cooling area length | 4m |

Veneer thickness and size | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/24h) | 180-190 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 8KW(18pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(4pc) |

Air intake fan | Power: 11KW(2pc) |

10 ton biomass burner | Power: 16.5KW |

Total power | 228.5KW |

Actual electricity consumption | About 160kwh per hour |

Overall Dimension(L*W*H) | 51m×13m×3.5m |

Certification

Customer Case

Factory

Packaging & Shipping