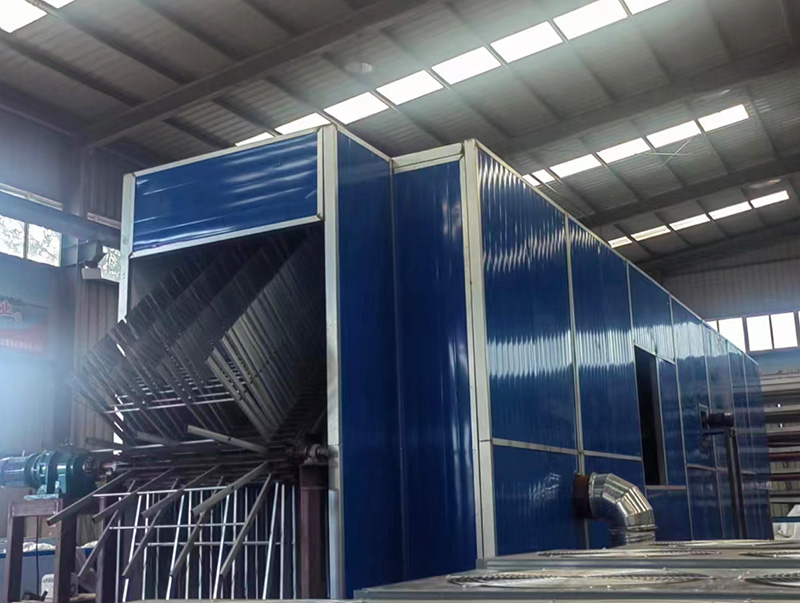

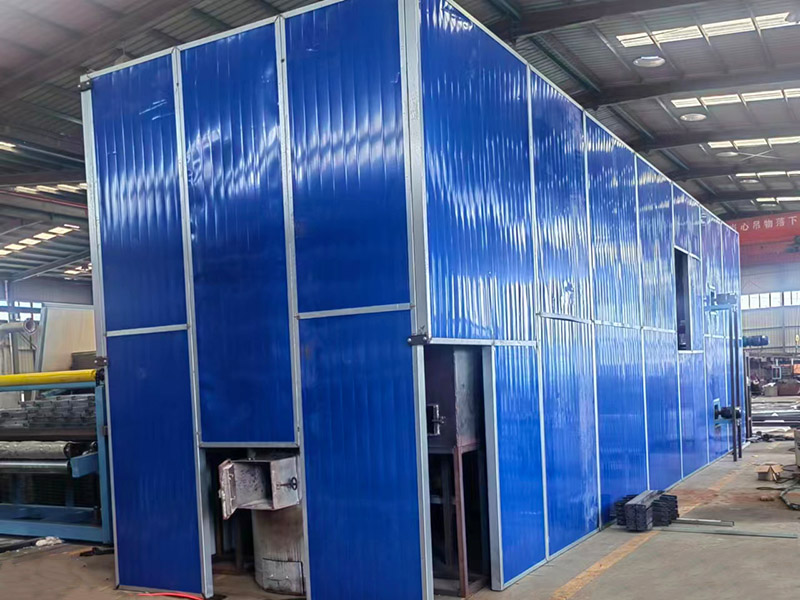

Vertical Core Veneer Dryer Kiln

The small vertical veneer dryer is a new drying equipment newly developed by Shine. It is energy-saving and power-saving, has a small footprint, is cheap, requires less labor, and has high drying efficiency.

Type: Vertical Veneer Dryer

Working Width: 3m

Veneer thickness: 0.8-8mm

Drying capacity (m³/day) : 36

Veneer Water Moisture: Fresh veneer to about 0-15%

Heat Source: Built-in Burner

Vertical Core Veneer Dryer Kiln

The Vertical Core Veneer Dryer Kiln can use the chain to bring the core veneer or finished board into the drying room for circulating drying. Energy saving, secondary use of hot air, fast heating, low power consumption, better drying effect, and less maintenance. The veneer tunnel drying machine can be manufactured according to customers' requirements. The veneer drying equipment adopts a co-current drying method. Flue gas and wet materials enter the dryer from the same side, and high temperatures can be used to obtain high evaporation intensity. The dryer outlet temperature is low and the thermal efficiency is high.

Working Principle:

The air volume, heating temperature, material residence time and feeding speed can be adjusted to achieve the best drying effect; the flap structure is adopted, and the space utilization rate is high. During drying, the material is constantly turned with the flap to ensure the consistency of product quality; The unique air distribution device makes the hot air distribution more in line with the needs of the material drying process.

Customer Case

The Factory

Packaging & Shipping