Jet Roller Veneer Dryer

Jet roller veneer dryer has the advantages of simple operation, safety and practicality, stable operation and easy maintenance. The processes of hot pressing-leveling-drying are finished at the same time.The veneer after drying is flat, smooth and without marks and the moisture content is uniform.

Jet Roller Veneer Dryer

Jet roller veneer dryer was equipped with automatic feeder device can feed the veneer to dryer and save labor cost mostly. The veneer after drying has uniform moisture content and it is flat without buckle or end waviness. Less maintenance is required for Shine veneer dryer machine and no veneer jamming leading to less downtime. Shine biomass veneer dryers machine can reach user's special requirements and achieve ideal drying effect mostly.

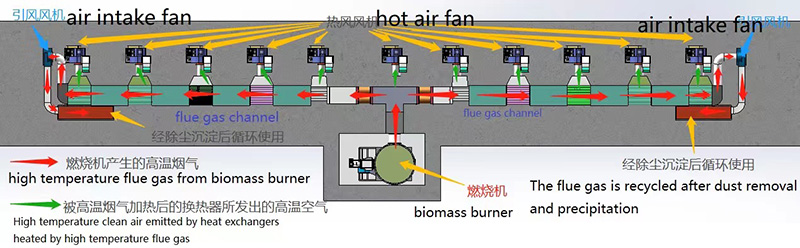

The working principle is that the veneer is clamped by the upper and lower seamless steel tube rollers, and the oven temperature reaches 140 ℃ by preheating, and then enters between the upper and lower rollers and blows high pressure hot air to the upper and lower sides of the veneer through the hot air pipe for rapid drying. So it can make the veneer smooth and moisture content even after drying, and it also has the characteristics of direct contact heat transfer between high temperature roller and wet veneer, high thermal efficiency, low heat loss and reducing heat energy consumption.

Product Parameters of Jet Roller Veneer Dryer

Model No | GTH30-52 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 48m |

Cooling area length | 4m |

Veneer thickness and size | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/h) | 6.7 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 4KW(48pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(4pc) |

Air intake fan | Power: 15KW(2pc) |

10 ton biomass burner | Power: 16.5KW |

Total power | 284.5KW |

Actual electricity consumption | About 200kwh per hour |

Overall Dimension(L*W*H) | 63m×11m×3.5m |

Project Case

Customer Visiting

Packaging & Shipping