Core Veneer Dryers Line

The electricity consumption of the shine veneer dryer has been reduced by 35%, and you can visit the case site nearby.

Type: Biomass Veneer Dryer

Working Width: 3m

Veneer thickness: 0.8-8mm

Heating Area Length: 54m

Drying capacity (m³/day) : 120-130

Heat Source: Biomass Burner (Other options available)

24 hours online service(WhatsApp:15806625431)

Core Veneer Dryers Line

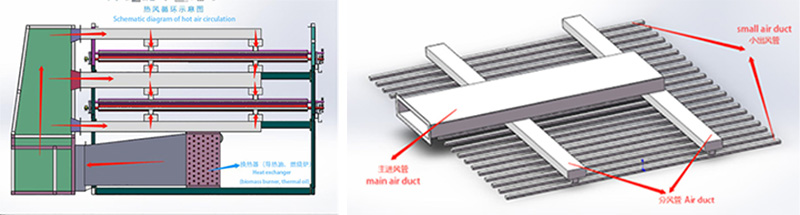

The 4 deck core veneer dryers line adopts a high degree of automation (the degree of automation can be customized) to save labor. The new axial flow fan reduces the power of the whole machine, which is both energy-saving and efficient. It adopts an advanced heat exchange structure, with high heat exchange efficiency and small heat loss. , the veneer dryer can be heated by a steam boiler, thermal oil furnace or biomass burner. Shine provides you with not only products, but also high-quality one-stop service solutions. From factory planning to put into use, Shine can Provide you with relevant suggestions.

Product Parameters of Core Veneer Dryers Line

Model No | GTH30-38 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 34m |

Cooling area length | 4m |

Veneer thickness and size | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | 120 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 11KW(17pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(8pc) |

Air intake fan | Power: 15KW(2pc) |

10 ton biomass burner | Power: 16.5KW |

Total power | 287.5KW |

Actual electricity consumption | About 200kwh per hour |

Overall Dimension(L*W*H) | 49m×11m×3.5m |

Customer Case

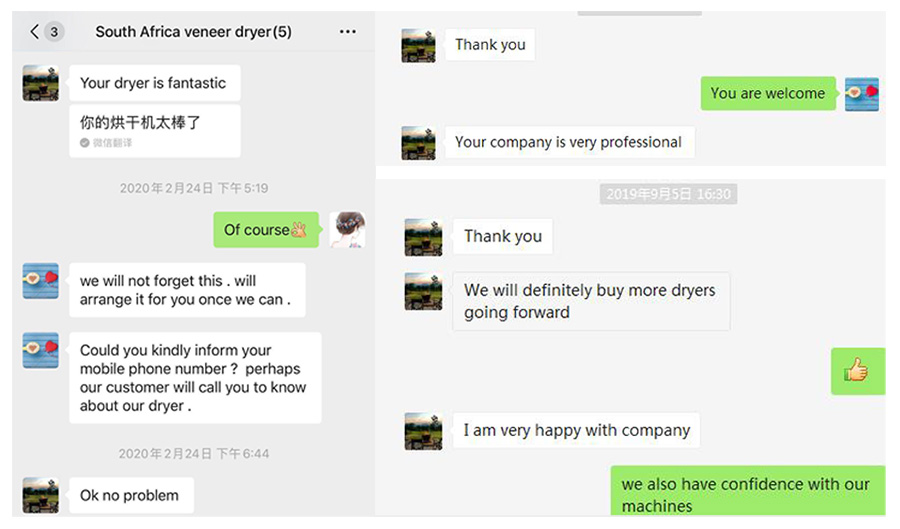

Customer Feedback

The Factory

Packaging & Shipping