Roller Veneer Jet Dryer

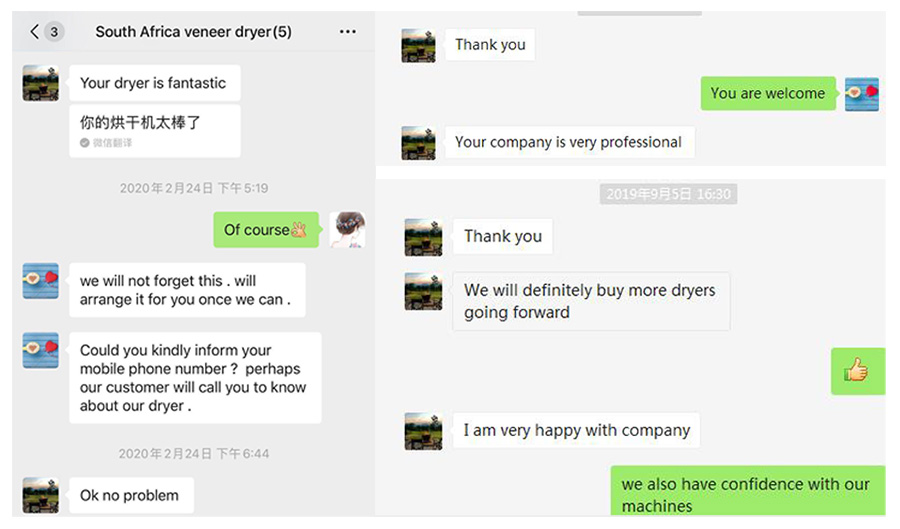

Shine customers come from more than 100 countries around the world. Due to the use of an axial fan, The power is half lower than the traditional dryer, and the automation is high (can be equipped with automatic feeding system and collection system). Late stage drying costs are 20% lower than traditional dryers.

If you want to know more details about the machine (performance, detailed parameters, videos, etc.), please contact us(WhatsApp: +8615806625431)

Roller Veneer Jet Dryer

veneer dryer machine equipped with new technology and advanced controlling system have been used for effective and quality drying veneers.Heat Thermal Oil as a type of hot air boiler,which is environmental friendly and energy saving.The most advantages of plywood veneer dryer is achieve lowest drying cost and perfect drying effect.

Advantages of Veneer Dryer Machine

1. The well-developed heat exchange system fully improves the energy utilization rate and saves unnecessary energy waste.

2. The control cabinet has automatic temperature control and speed regulation system, which can accurately control the final moisture content. Simple operation and low failure rate.

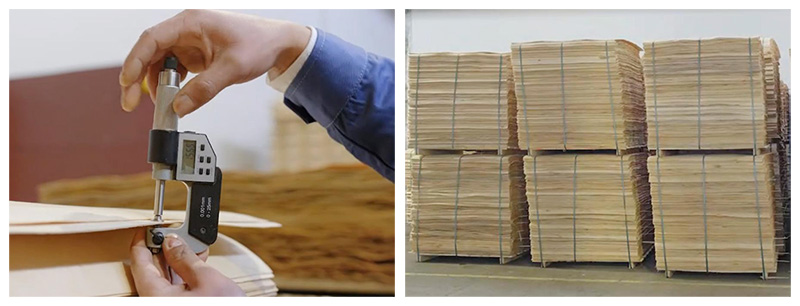

3. After drying, the veneer is smooth, with no cracks, wrinkles, or end ripples.

4. Shrinkage and hardening are kept to a minimum and veneer collapse and honeycomb structure are avoided.

5. We have a professional R&D team which can design different models according to customer’s special requirement.

Product Parameters of Veneer Jet Dryer

Model No | GTH30-44 |

Working Width | 3m |

Deck | 4 |

Roller material | Q235B, φ 102 special shaft tube |

Heating area length | 40m |

Cooling area length | 4m |

Veneer thickness and size | 1mm;1.2mm;2.4mm;3.5mm(2570*1370mm) |

Veneer water moisture | Fresh Veneers (above 70%) to about 10% |

Heating material | Thermal Oil |

Drying capacity | Minmum 125m³/day, Maximum 140m³/day |

Veneer transport speed | 5-22m/min, 16A chain |

Power of Hot Air Blower | 4kw (40pc) |

Power of Traction Motor | 5.5kw, frequency control (4pc) |

Power of Cold air blower | 4kw (4pc) |

Total Power | 198kw |

Actual electricity consumption | About 135kwh/ hour |

Overall Dimension(L*W*H) | 50m×4m×5m |

Exhibition and Customer Visiting

The customer evaluation

The Factory

Packaging & Shipping