Continuous Core Veneer Dryer Machine

Veneer Dryer Machine Advantages:

1. Customizable (customized one-stop service)

2. Professional factory production

3. The roller uses a φ89mm special shaft tube, which is corrosion-resistant and rust-proof

4. Diverse heat source options

5. The dryer output is 2-3 times that of the original traditional dryer

6. Air jet pipe: high-quality national standard galvanized rectangular tube.

Continuous Core Veneer Dryer Machine

The veneer dryer consists of two layers of conveying rollers. Each time the roller conveys the veneer through the upper and lower pressure rollers, it ensures that there is no veneer jam and the equipment runs continuously. The equipment running speed is 5-22 meters frequency conversion control (freely adjustable).

The veneer drying process consists of two parts: blowing heating by the blowing pipe and contact heating by the upper and lower pressure rollers. Double heating improves the heating efficiency.

Both the hot air blower and the cold air blower use 5.5kw axial flow fans, which not only fully guarantee the air volume required for drying, but also reduce the total installed power by more than 35%, and minimize the power consumption of the whole set of equipment.

Diversified heat sources are available. Our dryers can be equipped with a variety of heat sources, including steam boilers, thermal oil boilers, natural gas, burners, steam generators, etc.

Product Parameters of Core Veneer Dryer Machine

Model No | GTH30-52 |

Working Width | 3m |

Deck | 2 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 48m |

Cooling area length | 4m |

Veneer thickness | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/24h) | 75-85cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(12pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

6 ton biomass burner | Power: 16.5KW |

Total power | 125KW |

Actual electricity consumption | About 88kwh per hour |

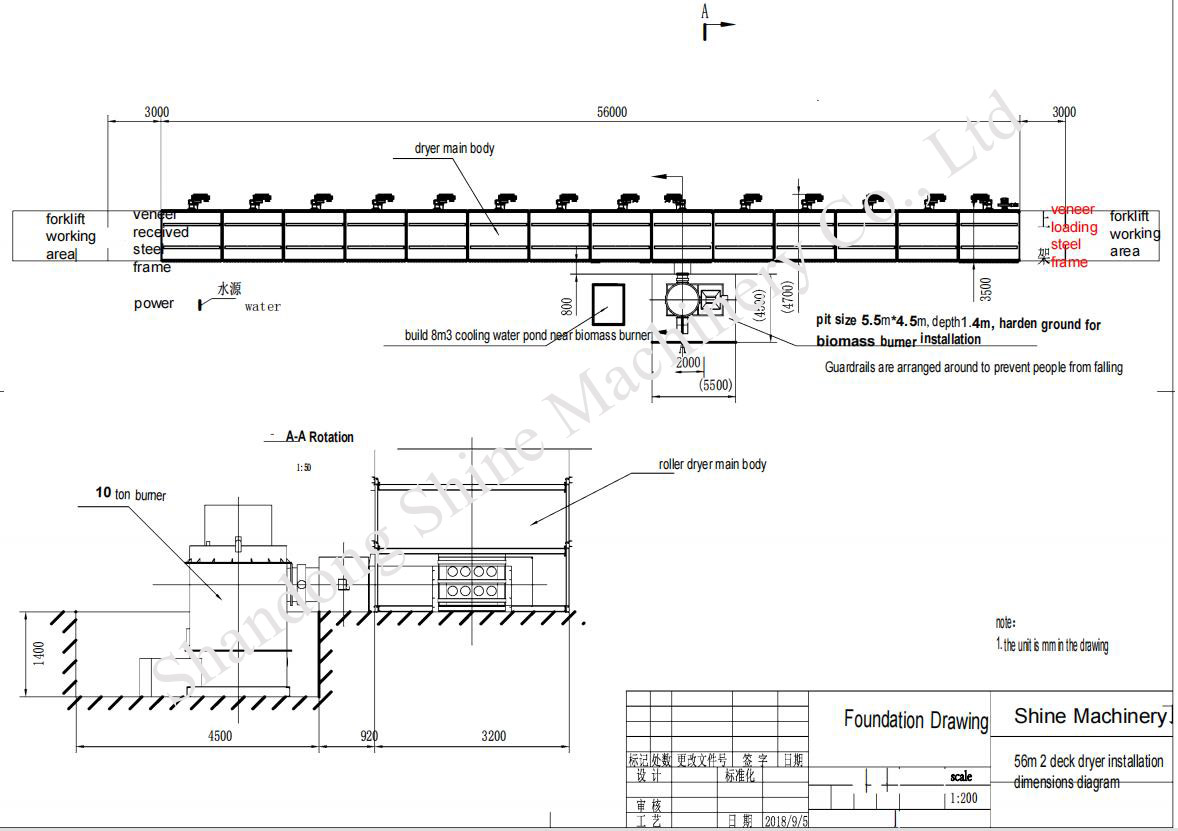

Layout of veneer drying machine

The moisture content of the dried veneer is uniform, flat, without wrinkles or end ripples, without cracks, and the surface bonding state is good, which avoids the phenomenon that a large number of veneers are over-dried or dried to fail to meet the process requirements.

Customer Case of Veneer Dryer

Shine veneer drying machine has been exported to more than 100 countries and regions, with agents in more than 50 different countries. Users can visit the case site nearby.

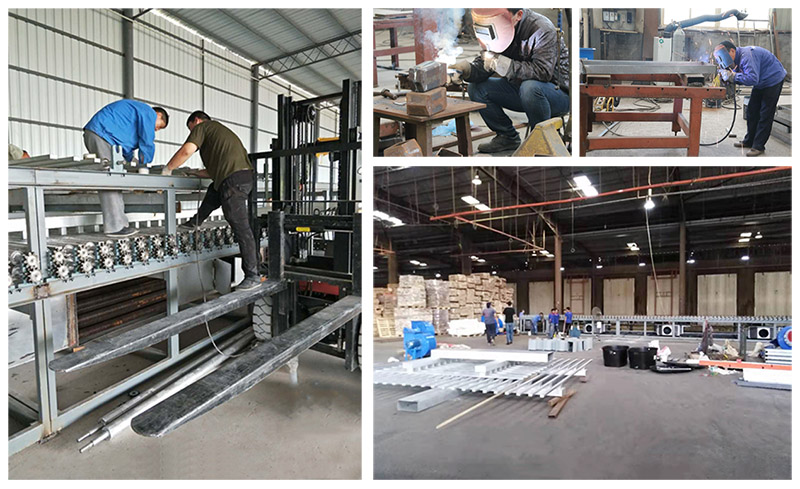

The Factory

Shine Machinery is a large-scale manufacturer specializing in R&D of wood veneer drying machine and veneer sheet peeling equipment. With decades fo growth, Shine Machinery has continuously improvved our equipment based on customer feedback. From out first dryer in 1999 to today's 4th generation of eco-friendly veneer prodution line, we are dedicated to relentless innovation, providing superior soutions.

The installation

We will send professional engineers to your factory to guide the installation and help train your factory workers to operate the equipment. The engineers will not return until the equipment is operating normally.

Packaging & Shipping

Похожие продукты

Отправлено успешно

Мы свяжемся с вами как можно скорее