Fully Automatic 4 Deck Veneer Dryer

1.Convenient installation (installation can be completed in 25-30 days)

2. The main electrical components are all well-known domestic and international brands

3.Flexible local support (technology and maintenance)

4.24-hour online service

5.Highly automated and efficient (fully automatic veneer feeding and collecting system)

6.The board is flat and wrinkle-free after drying

Fully Automatic 4 Deck Veneer Dryer

The 4 deck veneer dryer is easy to operate and has a low failure rate. Compared with traditional dryers, it has a good drying effect, the dried boards are flat and wrinkle-free, and the shrinkage rate is controlled at a very low level. The automated control system improves production efficiency.

The roller veneer dryer adopts advanced hot air circulation technology and precision control system, which can quickly and evenly dry various veneers to maintain their quality and stability. No matter what veneer you dry, it can meet your drying needs.

We not only provide a single device, but also provide a complete veneer drying solution. In addition to veneer dryers, we also provide supporting auxiliary equipment, technical training and customized services to meet the needs of different customers. Regardless of the size of your production, we can provide you with customized drying solutions to help you achieve greater success.

Product Parameters of Veneer Dryer

Model No | GTH30-44 |

Working Width | 3m |

Deck | 4 |

Roller material | Q235B, φ 102 special shaft tube |

Heating area length | 40m |

Cooling area length | 4m |

Veneer thickness and size | 1mm;1.2mm;2.4mm;3.5mm(2570*1370mm) |

Veneer water moisture | Fresh Veneers (above 70%) to about 10% |

Heating material | Thermal Oil |

Drying capacity | Minmum 125m³/day, Maximum 140m³/day

(with 24 working hours) |

Veneer transport speed | 5-22m/min, 16A chain |

Power of Hot Air Blower | 4kw (40pc) |

Power of Traction Motor | 5.5kw, frequency control (4pc) |

Power of Cold air blower | 4kw (4pc) |

Total Power | 198kw |

Actual electricity consumption | About 135kwh/ hour |

Overall Dimension(L*W*H) | 50m×4m×5m |

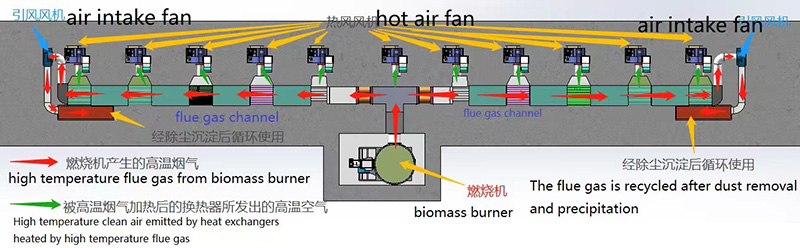

Veneer dryer Heat Exchange Process

Shine heat exchanger adopts step-by-step heat exchange, and the specifications of each section of the heat exchanger are different. The hot air in the heat exchanger can be evenly distributed to the veneer. The moisture content of the dried veneer is uniform, flat, without wrinkles or end ripples, no cracks, and the surface bonding state is good, which fully improves the utilization rate of energy and saves unnecessary energy waste.

Project Case

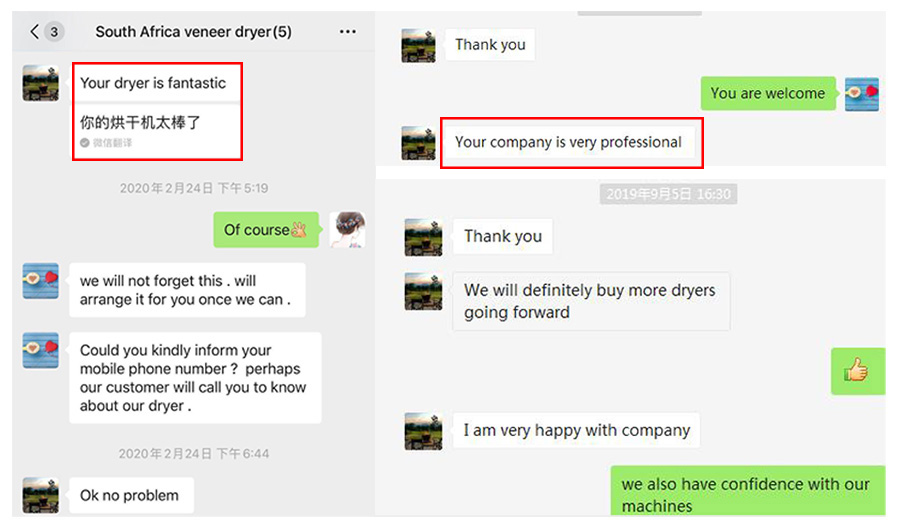

The customer evaluation

Our Services

Pre-sale services:

1) Provide the free consultation of all veneer dryer

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment.

3) Train the first-line operator.

After sale services:

1) 24 hours online service.

2) Provide the VIDEO with Install and debug the equipment.

3) Provide technical exchanging(Technical phone:+8615806625431)Door to door service is possible.

The Factory

Shine Machinery is a large-scale manufacturer specializing in R&D of wood veneer drying machine and veneer sheet peeling equipment. With decades fo growth, Shine Machinery has continuously improvved our equipment based on customer feedback. From out first dryer in 1999 to today's 4th generation of eco-friendly veneer prodution line, we are dedicated to relentless innovation, providing superior soutions.

The installation

Our engineers went to the customer's factory to guide the installation of the veneer dryer machine. With the cooperation of the customer, the four-layer veneer dryer was installed in a short time. During this period, we established a deep relationship with the customer and took a group photo. Take a souvenir. The user is very satisfied with our entire service process and drying equipment. We will continue to purchase our veneer dryers when we expand production in the future.

Packaging & Shipping