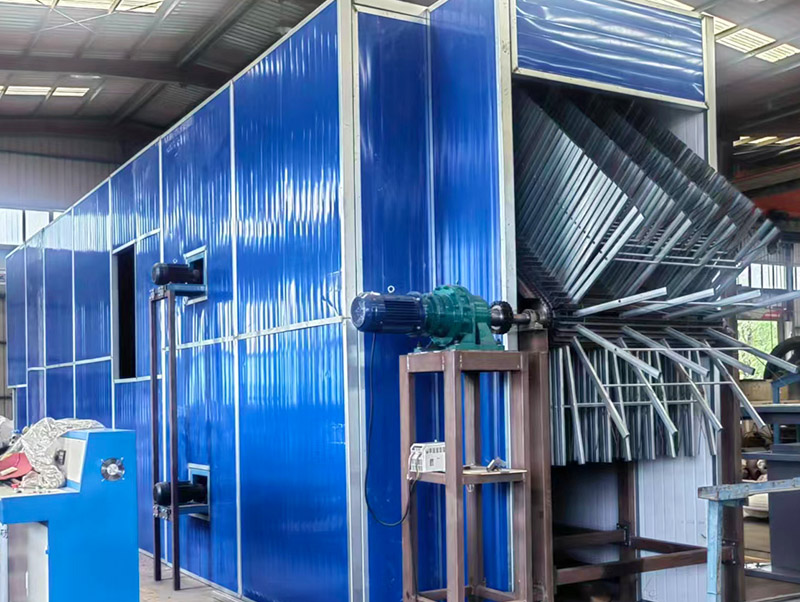

Wood Vertical Veneer Dryer

1.Small footprint, with a length of about 20 meters and a width of about 7 meters, reduces investment in factory construction and saves factory space.

2.Adopting a reciprocating design, the heat energy is effectively utilized, and it can dry about 1.5 cubic meters per hour with high drying efficiency.

3.Equipped with a temperature controller, it can control the temperature within 110-140 degrees Celsius, ensuring safe production while ensuring production efficiency.

The Vertical Veneer Dryer is Designed to maximize productivity while minimizing space requirements, this machine is perfect for manufacturers with limited floor space. The vertical drying process ensures a fast, consistent result, making it suitable for a wide range of veneer thicknesses. With its energy-efficient design and affordable price, the Vertical Veneer Dryer delivers outstanding performance and value for money.

Product Parameters of Vertical Veneer Dryer

Model | FBH30-20 |

Moisture Content(%) | Fresh veneer to within 20% |

Capacity(m³/H) | 1.2-1.5 |

Overall Size | 20 X 7 X 4 |

Hot Air Blower(KW) | 1.5kw X 6set=9KW |

Traction Motor(KW) | 4KW |

Intake Air Blower(KW) | 7.5KW |

Internal Burner Blower (KW) | 1.1KW |

Oil Station Power | 2.2KW |

Water Pump Power

| 2.2KW |

Chain Conveyor | 2.2KW |

Infeed Conveyor Belt

| 2.2KW |

Side Entry Feeding

| 2.2KW |

Veneer Collecting | 2.2KW |

Cooling Blower (Above burner) | 0.75kw*2set=1.5KW |

Total Power(KW) | 36.3KW |

Exhibition and Customer Visiting

The Factory

Packaging & Shipping