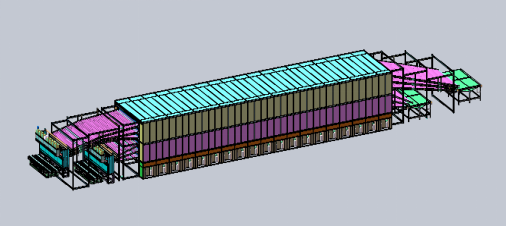

High Efficiency 6 deck Veneer Dryer

The wood veneer dryer has a variety of different drying configurations to suit a variety of drying needs are available. The length, width, and layers of the core veneer dryer can be designed and made for customers. High degree of automation (the degree of automation can be customized),Flexible Local Support (Technicals & Maintenance)

Working Width: 3-6m

Veneer thickness: 0.8-8mm

Veneer Water Moisture: Fresh veneer to about 0-15%

Heat Source: Biomass Burner (Other options available)

24 hours online service(WhatsApp:+8615806625431)

This 6 deck veneer dryer is specially designed for efficient and stable veneer drying needs, with an excellent level of automation and an advanced heating system. The equipment adopts a 6 deck conveyor roller design, and the veneers are smoothly transported through the upper and lower pressure rollers to ensure uninterrupted operation during the entire drying process and reduce production stagnation. The operating speed of the equipment can be flexibly adjusted within the range of 5-22 meters through frequency conversion control according to production needs, truly achieving the perfect combination of high speed and flexibility.

The dual heating system is a highlight of this equipment: the air duct blowing heating combined with the upper and lower pressure roller contact heating significantly improves the heating efficiency and ensures that the veneer can achieve the ideal drying effect in a short time. This dual heating method not only increases the drying speed, but also ensures the drying uniformity of the veneer, thus improving product quality.

The fully automatic plate feeding system further optimizes the production process, reduces the risk of misalignment when manually feeding the plates, and ensures that the veneers run smoothly and smoothly in the dryer to avoid clogging. In addition, it greatly reduces manual labor intensity and improves production efficiency, allowing you to significantly reduce labor costs while ensuring quality.

When you choose this 6 deck veneer dryer, you will have:

Efficient and stable automated operation reduces manual intervention.

Dual heating system achieves more efficient drying performance.

Flexible frequency conversion speed regulation to meet different production needs.

Automatic plate feeding system ensures a stable and smooth production process.

Reduce manual labor intensity and improve overall production efficiency.

This equipment not only provides reliability to your production process, but also significantly improves the efficiency of the enterprise.

Product Parameters of Veneer Dryer

Model | GTH612-42 |

Deck | 6 |

Working Width(M) | 6120mm |

Hot Air Section(M) | 36m(2m/section, 18sections in total) |

Cold Air Section(M) | 6m (2m/section, 3 section in total) |

Moisture Content(%) | Fresh Veneers to within 12% |

Drying (℃) | 160-180℃ adjustable. |

Drying Capacity(M3/H) | 15-18m3/hour |

Veneer Speed(M/MIN) | 5-22m/min,16A Chain |

Power of Hot Air Fan (KW) | 2pcs×15KW×18section=540KW |

Power of Traction Motor(KW) | XWD6 Reducer Frequency Control |

Power of Cold Air Fan(KW) | 2pcs×15KW×3section=90KW |

Power of Dehumidifying Fan(KW) | 5.5KW×1pc=5.5KW |

Total Power | 680.5KW |

Power Consumption | About 410kwh |

Overall Dimension | 65453 X 22080 X 5500 mm |

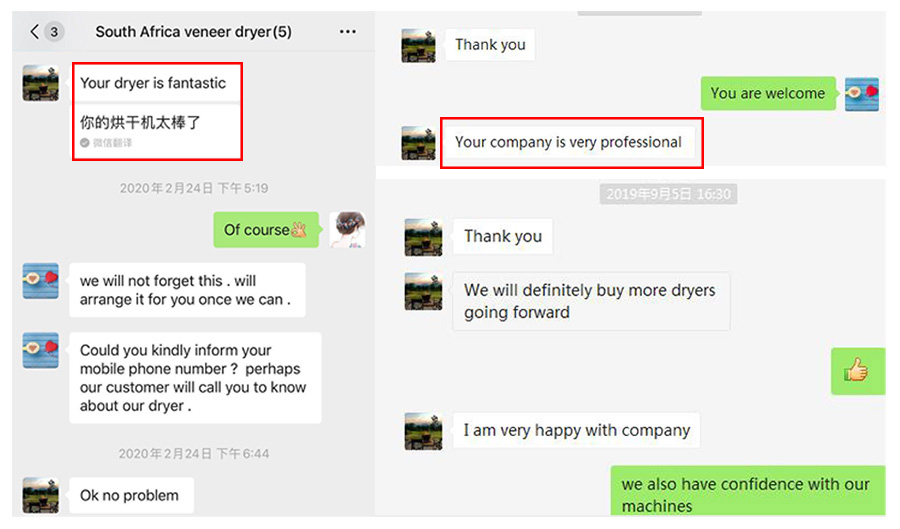

Customer Case

The customer evaluation

The Factory

Packaging & Shipping