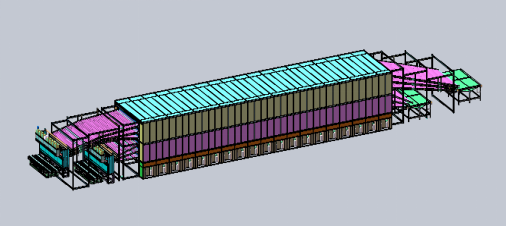

New Type Core Veneer Dryer

1.Customizable (customized one-stop service)

2. Professional factory production

3.Highly automated and efficient (fully automatic veneer feeding and receiving system)

4.Stable equipment and low failure rate

5.Imported accessories, using thicker high-quality steel

6.The veneer is flat and wrinkle-free after drying

The drying machine consists of six layers of conveyor rollers, with each roller transporting veneers through upper and lower pressure rollers to ensure obstruction-free veneer conveyance, thus ensuring continuous equipment operation. The operating speed of the equipment is controlled by variable frequency within the range of 5-22 meters (adjustable as needed).

Automatic veneer feeding reduces the probability of veneer misalignment caused by manual feeding, ensuring smooth and stable movement of single boards inside the dryer, thus avoiding potential blockage risks. Additionally, it significantly reduces manual labor and intensity, thereby improving production efficiency.

Product Parameters of Core Veneer Dryer

Model | GTH612-42 |

Deck | 6 |

Working Width(M) | 6120mm |

Hot Air Section(M) | 36m(2m/section, 18sections in total) |

Cold Air Section(M) | 6m (2m/section, 3 section in total) |

Moisture Content(%) | Fresh Veneers to within 12% |

Drying (℃) | 160-180℃ adjustable. |

Drying Capacity(M3/H) | 15-18m3/hour |

Veneer Speed(M/MIN) | 5-22m/min,16A Chain |

Power of Hot Air Fan (KW) | 2pcs×15KW×18section=540KW |

Power of Traction Motor(KW) | XWD6 Reducer Frequency Control |

Power of Cold Air Fan(KW) | 2pcs×15KW×3section=90KW |

Total Power | 680.5KW |

Power Consumption | About 410kwh |

Exhibition and Customer Visiting

The Factory

Packaging & Shipping