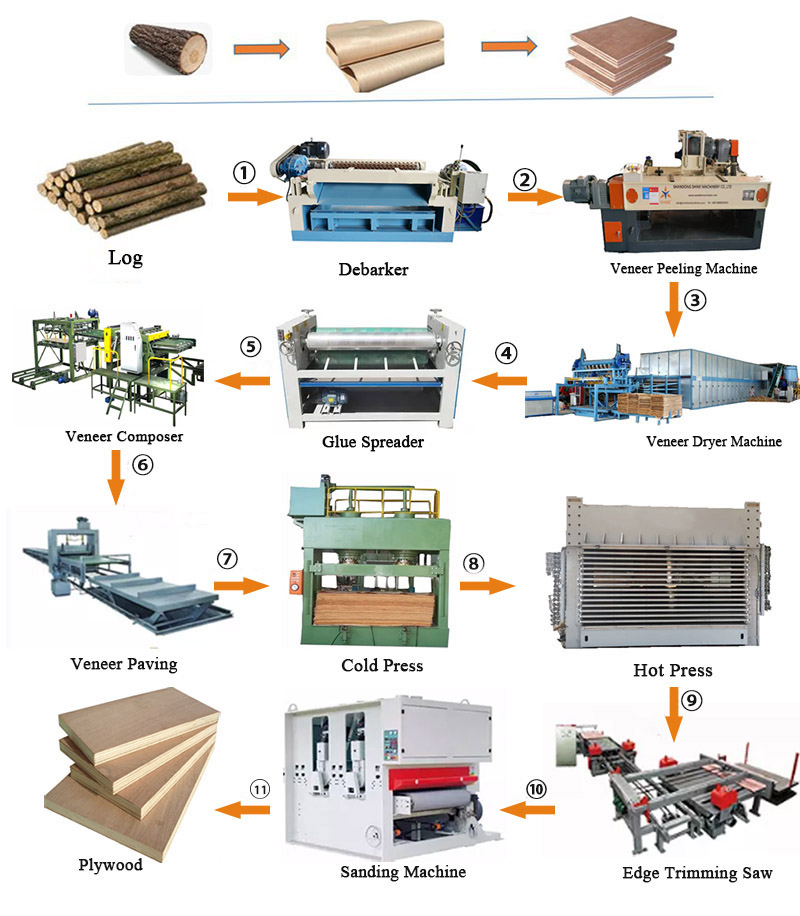

Plywood production process

The production process of plywood is a multi-step process involving raw material processing, veneer production, gluing and pressing, and post-processing. Here are the main production processes:

1. Log processing

Cut: Cut logs into lengths suitable for peeling or planing (usually 2.6 meters or customized sizes).

Debarking: Remove bark to reduce the impact of impurities on subsequent processes.

Cooking and softening (optional): Soak or cook logs (temperature about 60-80℃) to soften wood fibers for peeling.

2. Veneer production

Pearl cutting (main process):

Fix the softened logs on the peeling machine and rotate to cut out continuous veneers (thickness 0.1-4mm).

Planing (special needs):

For wood with high texture requirements (such as decorative panels), planing is used to obtain veneers with straight grain or special patterns.

Veneer drying:

The moisture content of the veneer is reduced to 6-12% through a veneer dryer (temperature 70-120℃) to prevent deformation after gluing.

3. Veneer finishing

Sorting and repairing:

Remove defective veneers such as cracks and wormholes, and repair small holes or cracks.

Gluing:

Apply adhesive (usually urea-formaldehyde resin, phenolic resin or environmentally friendly glue) evenly on the surface of the veneer, with an amount of about 100-300g/m².

4. Assembly (overlapping)

Structural design:

Overlap veneers (odd number of layers, such as 3 layers, 5 layers) according to the principle of "vertical wood grain of adjacent layers" to ensure balanced strength.

Symmetrical arrangement:

Use high-quality veneer for the surface layer, and thicker or low-cost wood for the core layer.

5. Hot pressing

Pre-pressing (optional):

Preliminary pressure fixation of the veneer to reduce misalignment during hot pressing.

Hot pressing:

In a hot press (temperature 110-140℃, pressure 1.0-1.5MPa, time 1-1.5 minutes/mm thickness), the adhesive is cured to form a stable board.

6. Post-processing

Cooling and curing:

Naturally cool and stand for 24-48 hours to release internal stress and stabilize the size.

Trimming and sanding:

Cut into standard size (such as 1220×2440mm), sand the surface until it is flat and smooth.

Grading and inspection:

Grade strength, moisture content, and appearance according to national standards (such as GB/T 9846).

7. Special treatment (optional)

Veneer treatment: additional decorative layer (such as veneer, melamine impregnated paper).

Functional treatment: moisture-proof (phenolic glue), fireproof (flame retardant immersion), anti-corrosion (chemical treatment), etc.

Key control points

Veneer quality: uniform thickness and no defects.

Adhesive selection: environmental protection (such as E0/E1 grade), water resistance.

Hot pressing parameters: temperature, pressure, and time must match the type of glue and thickness.

Moisture content control: avoid warping or cracking of the board.

Application areas: building formwork, furniture manufacturing, packaging boxes, ships, etc.