Biomass Veneer Drying Machine

Shine biomass veneer dryer has the features of high productivity, energy efficiency, lowest drying cost and perfect drying effect. The composite cost is only about $6-12/cubic meter, which can improve customers profit space greatly.

Working Width:3m

Veneer thickness:0.6-8mm

Heating area length:36m

Drying capacity (m³/24h):180-200

Heat source:10 ton biomass burner

Biomass Veneer Drying Machine

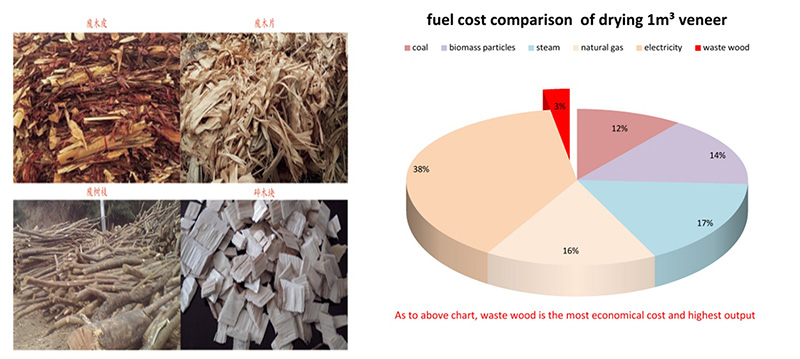

Shine biomass burner veneer drying machine which is our patented product. It can burn all kinds of waste wood directly to reduce the drying cost mostly.

Biomass burner can effectively treat surplus waste crops such as sawdust and straw. Its fuel can be: waste wood corn cob crop straw compost, etc., The environmentally friendly biomass pellet fuel equipment produces products that are environmentally friendly, energy efficient, cost effective, and low cost.

The Main advantages of Biomass Burner

1.patented product and Save fuel

2.Smokeless, energy saving and environmental

3.high efficenency, veneer dryer drying is not easy to deformation, low damage rate, high product rate.

4.Low cost,waste wood does not need to be dried in the sun and can be burned directly, reducing the cost of drying.

Shine heat exchanger adopts step by step heat transfer, and the specifications of each section of the heat exchanger are different, and the hot air in the heat exchanger can be uniformly emitted to the veneer. The veneer after drying has uniform moisture content, flat, no buckle or end waviness; free of splits and the surface is in good condition for gluing.

Product Parameters of Biomass Veneer Drying Machine

| Model No | GTH30-32 |

| Working Width | 3m |

| Deck | 2 |

| Heating area length | 28m |

| Cooling area length | 4m |

| Veneer thickness | 0.6-8mm |

| Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200℃C adjustable. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

| Drying capacity (m³/day) | 40-45cbm |

| Veneer transport speed | 5-22m/min,16A chain |

| Hot air blower | Power:5.5KW(7pc) |

| Traction motor | Power: 7.5KW,frequency control(2pc) |

| Cold air blower | Power: 5.5KW(1pc) |

| Air intake fan | Power : 7.5KW(2pc) |

| 4 ton biomass burner | Power: 16.5KW |

| Total power | 90.5KW |

| Actual electricity consumption | About 95kwh per hour |

Certification

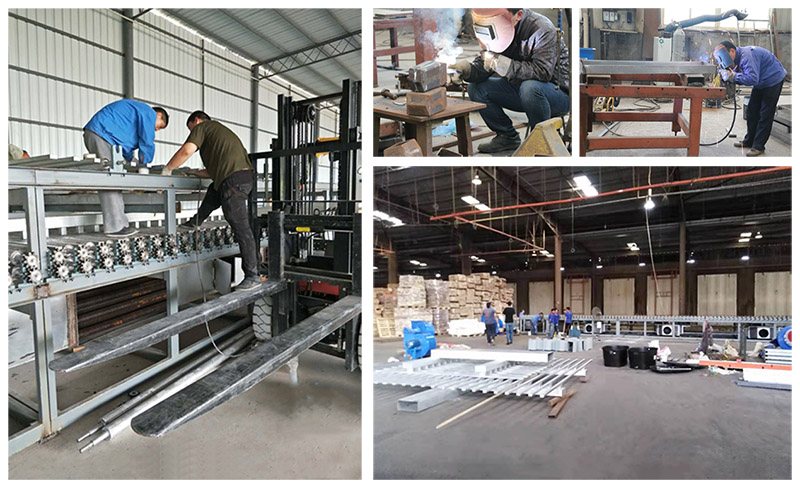

The installation

Customer Visit

Our Services

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine.

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Overseas install and debug the equipment.

3) Train the first-line operator.

After sale services:

1) 24 hours online service(WhatsApp:+8615806625431)

2) Provide the VIDEO with Install and debug the equipment.

3) Provide technical exchanging(Technical phone:15665878109)Door to door service is possible.

Packaging & Shipping