Roller Veneer Dryer

The electricity consumption of the shine veneer dryer has been reduced by 35%, and you can visit the case site nearby.

Type: Roller Veneer Dryer

Working Width: 4.5m

Veneer thickness: 0.8-8mm

Heating Area Length: 54m

Drying capacity (m³/day) : 120-130

Heat Source: Biomass Burner (Other options available)

24 hours online service(WhatsApp:15806625431)

Roller Veneer Dryer

The roller veneer dryer machine is one of the essential machines in the plywood-making line. The feeding width and working length as well as the layers/decks of the wood veneer dryer can be customized in line with the specific production capacity needed by different customers. lowest drying cost and perfect drying effect.

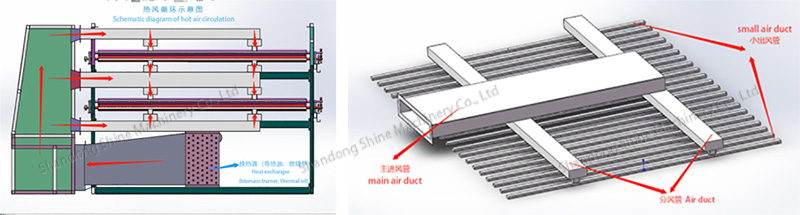

Wood roller veneer dryer has an advanced heat exchanging structure with features of high heat exchange efficiency and low heat loss. The core veneer dryer can be heated by a steam boiler, thermal oil heater, or biomass burner which can save the fuel cost the most. The composite drying cost using biomass burner heated roller dryer is about only USD 10 per cubic meter including the labor cost, fuel cost, and electricity.

The Roller Veneer Dryer Humidity Removal System is installed on the top of the Shine’s veneer dryer to quickly and discharge the moisture inside the dryer to the outside of the workshop, avoiding the pre-condensation of steam caused by the temperature difference between the inside and outside of the dryer, and keeping the inside of the dryer dry and pressure balanced.Specially designed for users in northern cold regions. It can be installed on any dryer model of our company separately. The thermal insulation system is specially designed for cold regions such as Russia, and the thermal insulation system of the fan is added.

The biomass burner is Shine patented product. It can burn all kinds of waste wood directly to reduce the drying cost mostly. Compared to steam type or heat conduction oil type veneer dryer, the drying cost is reduced greatly.

Product Parameters of Roller Veneer Dryer

Model No | GTH45-56 |

Working Width | 4.5m |

Deck | 2 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 52m |

Cooling area length | 4m |

Veneer thickness | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/24h) | 120cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(13pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 15KW(2pc) |

10 ton biomass burner | Power: 16.5KW |

Total power | 161.5KW |

Actual electricity consumption | About 113.5kwh per hour |

Covered Space of the whole machine | 62M X 12M X 3M |

Case Video of Roller Veneer Dryer

Certification

Our Factory

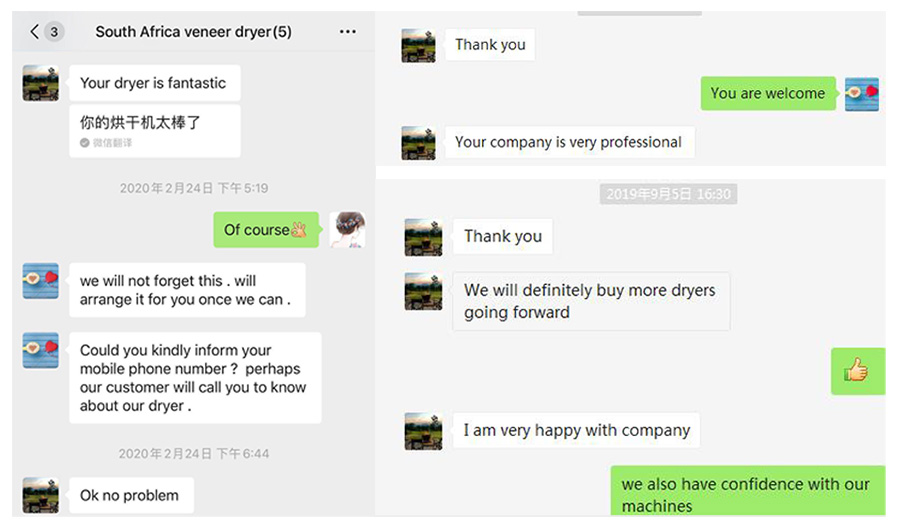

The customer evaluation

Our Services

Pre-sale services:

1) Provide the free consultation of all wood roller veneer dryer

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging(Technical phone:++8615806625431)Door to door service is possible